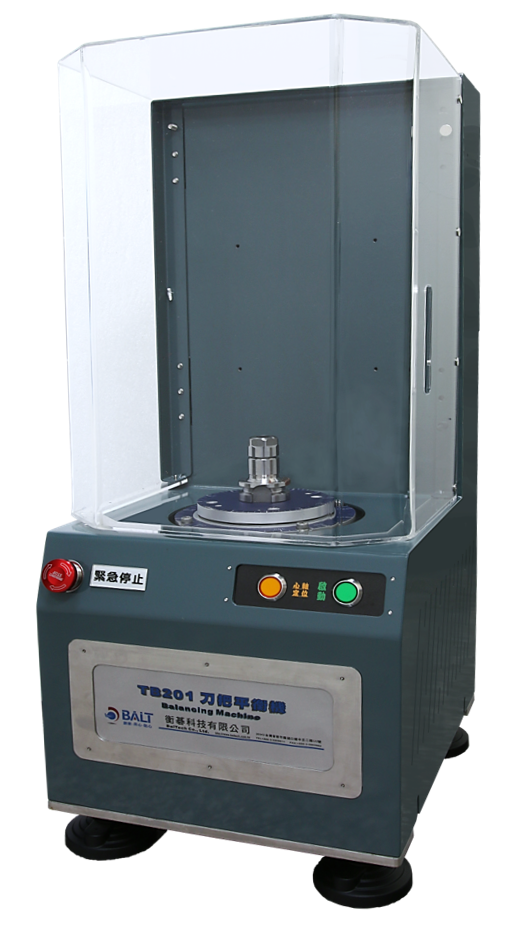

- Be Applicable for Various Tools - According to the demand of mass production, balance tools to decrease machine vibration. TB-201 is the indispensable equipment for improving performance and quality.

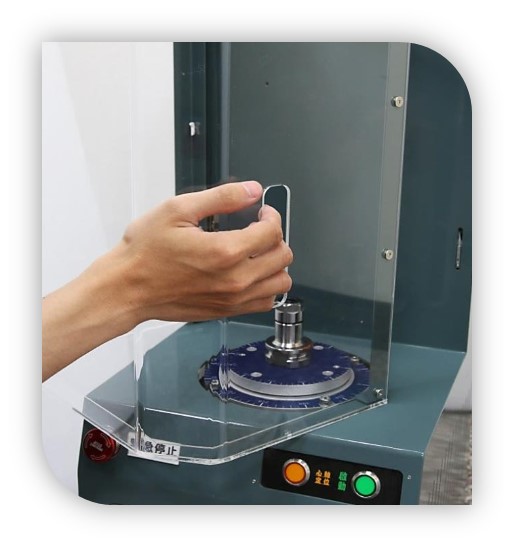

- High precision chuck spindle - The precision of chuck determines the accuracy of balancing machine.

- Replaceable chuck spindle - Be applicable for various tool types.

- Easy Operation - Balance tools with only entering the radius and without adding trial weight.

- Automatically Chuck the Tool - Fast load and unload tool to increase the productivity.

- Stable Machine Base - Can be installed on the table to increase the flexibility.

Comply with ISO 21940-23 Standard - Safety equipment prevents damage from tools.

左右滑動看表格

左右滑動看表格| TB201 Advantage Characteristics | |||||

| Balancing Type | Single | Units | ug/mg/g/ kg | ||

| Display Type | Radar Diagram | Measurement Mode | High precision / Fast | ||

| Language | Traditional Chinese / Simplified Chinese / English | Clay Hint | Yes | ||

| Operating System | Win7/8/10 | Components | Yes | ||

| Auto Determine OK/NG | Yes | Verification with Standard Rotor | Yes | ||

| Background Noise Detect | Yes | Add / Remove Mass to Balance | Yes | ||

| Auto Return to Origin | Yes | ISO 1940 Calculator | Yes | ||

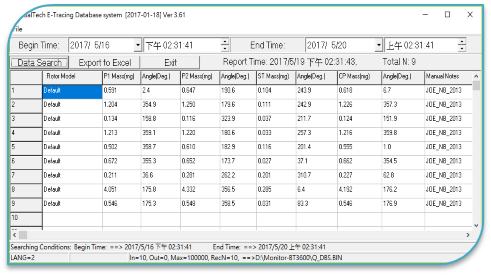

| Spectrum Analyzer | Yes | Export as Excel Format | Yes | ||

| File Management of Parameters | Yes | Online Database | Yes | ||

| RS232 Output | (option) | Chuck Count Hint | Yes | ||

| Productivity Statistics | Yes | Last Radar Diagram | Yes | ||

| TB201 Hardware Specification | |

| Type of unbalance detection | single planes measurement |

| Maximum tool diameter [mm] | 120mm |

| Maximum tool length [mm] | 300mm |

| Maximum tool weight [kg] | < 8 kg |

| Maximum measuring speed | 800 - 1,700 (rev/min, RPM) |

| Resolution of rotating speed | < 2% |

| Minimal unbalance (note) | <0.5 (g-mm) |

| Automatic positioning | Server motor control |

| Power usage [W] | 400 ~500 Watt. |

| Controller connection type | USB 3.0 Plug and Play |

| External communication interface | RS232 (option) |

| Mechanical size (L x W x H) | 360.0 x 310.0 x 770.0 (mm) |

| Weight of balancing machine | < 68.0 Kg |

| Power requirement | 200 - 220V (Single phase , 50 or 60Hz) |

| Air source pressure requirement | 5.0 – 6.0 Kg/cm^2 |

| Environmental temperature | 10 – 60 degree C |

| Environmental humidity | 25% - 80% |