Product Features :

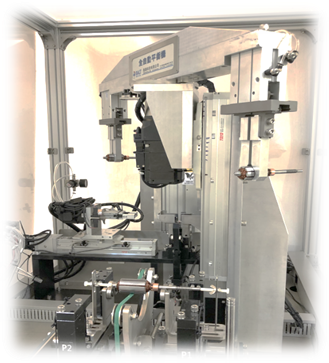

- Auto Scheduling Robotic Arm

- Double-station, Double Capacity

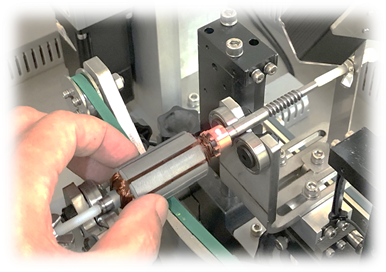

- Measuring and Milling at the same time

- 4-Axis Simultaneous CNC Milling Machine

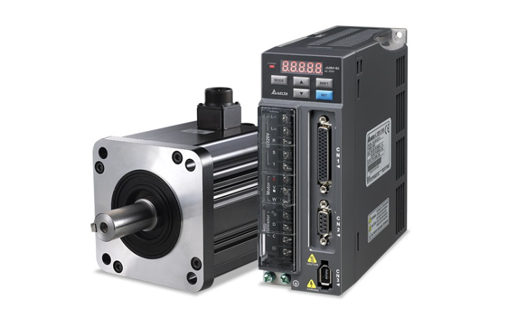

- Servo Control System

- Double-station, Half Cycle Time

- Industry 4.0 upgrading

- Production Management Visualization

- Traceable Manufacturing Database

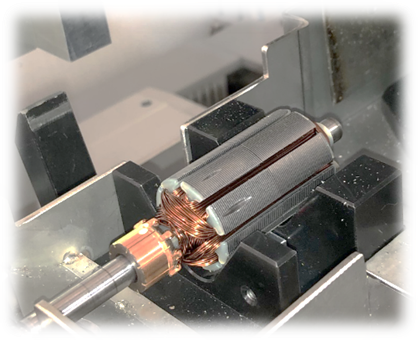

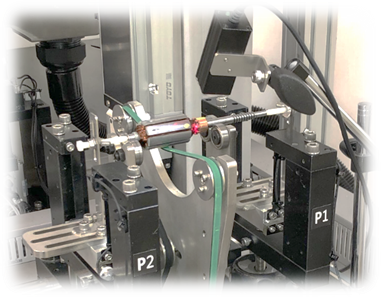

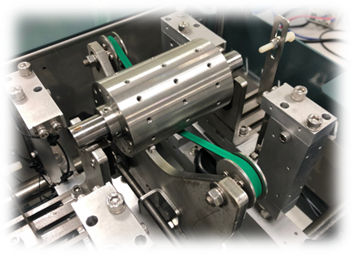

- High precision unbalance measuring station - Replaceable double rolling bearing design makes loading and unloading rotor more convenient and changing model faster.

- AI balancing program - Two stations operate at the same time by using advanced DSP technology to exclude interference from milling station.

- Easy Operation, Get Started Quickly

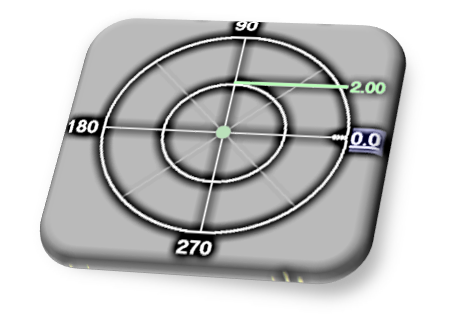

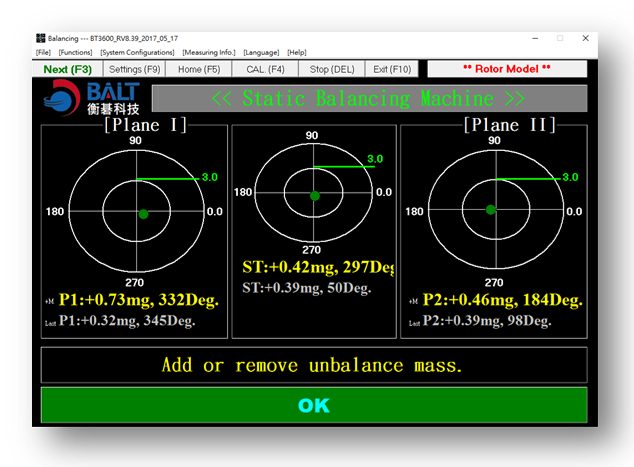

- Results Display with Single, Dual and Static Plane

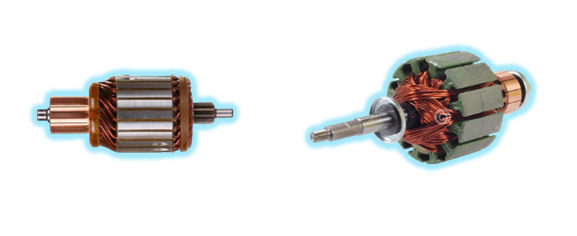

- Flexibly Apply for Adding and Removing Mass Balancing

- Determine OK/NG Automatically

- Graphical Radar Map

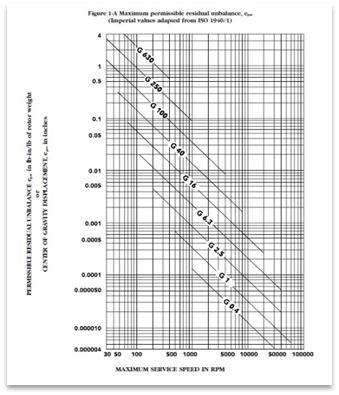

- Set Up Tolerance with ISO 1940

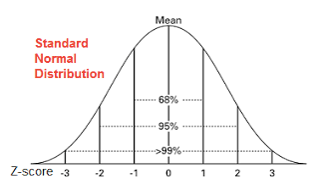

- Excel Format Statistics and Report

- Real-time Monitor the Interference from Enviroment

- Statistics visualize the production information and digitize the management.

- Record and organize measuring data automatically make it as efficient information to benefit the quality control.